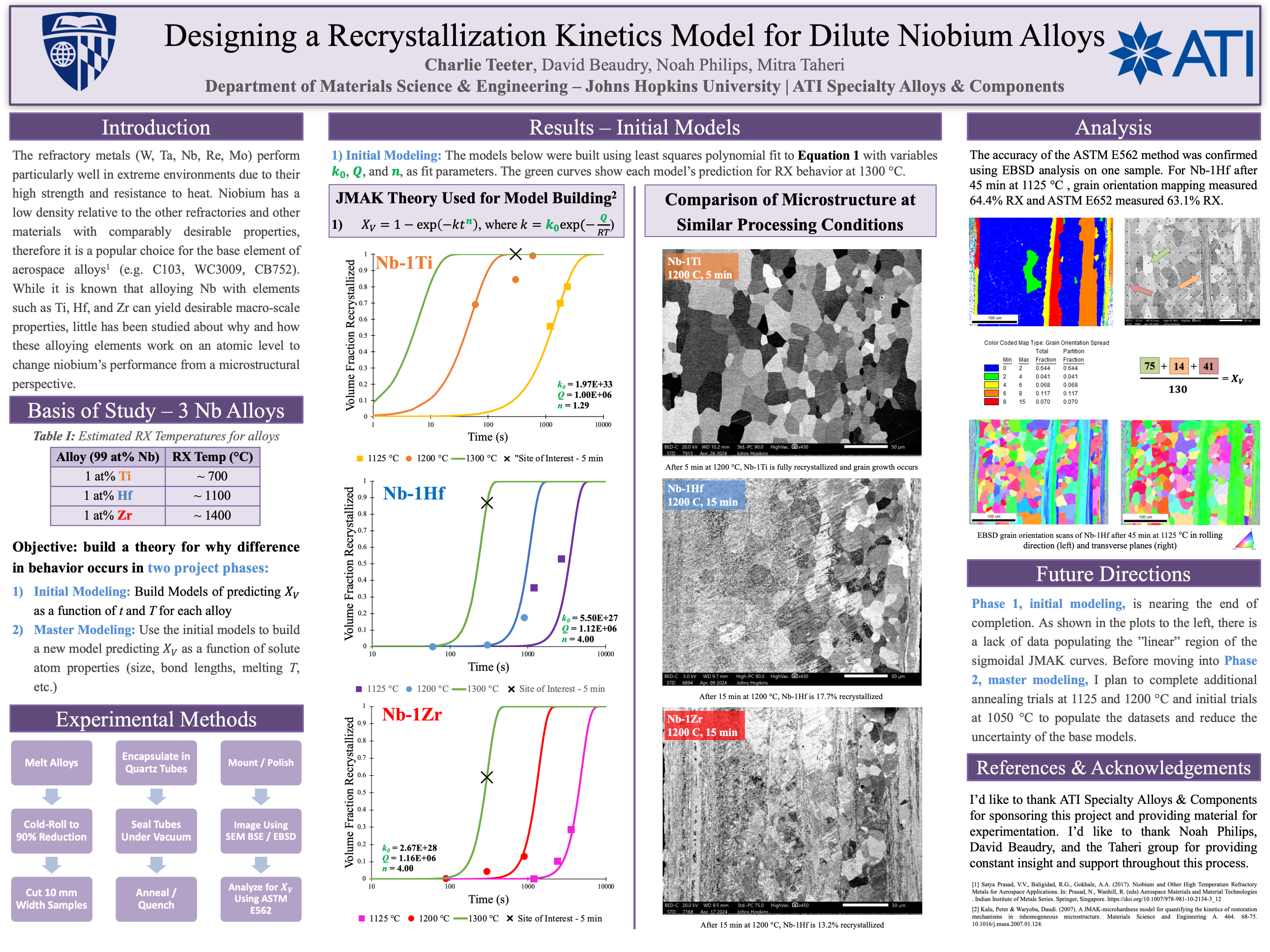

Designing a Recrystallization Kinetics Model for Dilute Niobium Alloys

- Program: Materials Science and Engineering

- Course: EN.510.434 MSE Senior Design

Project Description:

While it is known that alloying niobium with elements such as Ti, Hf, and Zr can yield desirable macro-scale properties for extreme environment applications, little has been studied about why and how these alloying elements work on an atomic level to change niobium’s performance from a microstructural perspective. This project, sponsored by ATI Specialty Alloys & Components, aims to build a theory to explain how different solute atoms affect microstructural evolution of niobium by designing a system of models that will predict the recrystallization behavior of dilute Nb alloys as a function of annealing conditions. Charlie’s research focuses on designing a system of models comparing Nb-1Ti, Nb-1Hf, and Nb-1Zr (atomic %) that will be used in the future to build a master model predicting the recrystallization behavior of any two component alloy that is 99% niobium

Project Mentors, Sponsors, and Partners

- ATI Specialty Alloys & Components

- Noah Philips

- David Beaudry