Finite Element Analysis & Topology Optimization of Biodegradable Magnesium-Alloy Intramedullary Rods

Team: C.I.R.D.

Program:

Materials Science and Engineering

Project Description:

Long-bone fractures are a common civilian and combat related injury. These injuries are slow to heal due to limited blood flow, and typically require surgical intervention in order for the fracture to stabilize. Traditional surgical methods leverage intramedullary rods made of stainless steel or titanium however, the stiffness of these materials is much greater than that of the surrounding bone. This disparity in mechanical properties between implants and surrounding bone results in stress shielding as the majority of stresses from loading are applied through the implant rather than the bone. Stress shielding can result in incomplete healing of the bone, or bone loss. The stress-shielding effects presented by traditional implants can be mitigated by using Magnesium-based intramedullary rods. Magnesium alloys have mechanical properties similar to that of bone, and are biodegradable, allowing the implants to dissolve as the surrounding bone heals, reducing risks associated with implant removal surgeries.

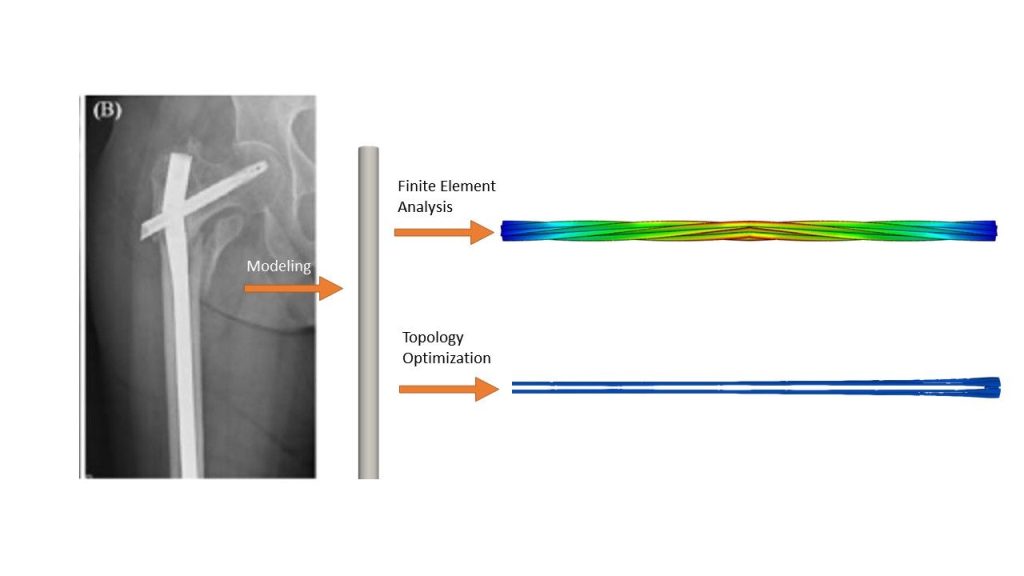

The goal of our work is to optimize the geometry of magnesium intramedullary rods (IRs) to improve bone loading for growth and recovery in long bone fractures through finite element analysis (FEA) and topology optimization (TO).

Team Members

-

[foreach 357]

[if 397 not_equal=””][/if 397][395]

[/foreach 357]

Project Mentors, Sponsors, and Partners

Professor James Guest

Justin Unger

Professor Timothy Weihs

Course Faculty

-

[foreach 429]

[if 433 not_equal=””][/if 433][431]

[/foreach 429]

Project Links

Additional Project Information

Project Photo

Project Photo Caption:

From left to right: X-Ray of traditional intramedullary rod in a femur, a modeled cylindrical rod, a FEA modeled rod under torsional load, and a topology optimized rod